6 Printing Processes

Have a large order? One that might jeopardize another client’s timeline?

At Bandanna Warehouse, we believe that an eye-catching product starts with an eye-catching design. That’s why we offer a range of options for the imprinting process, creating completely custom designs for your clients using our six in-house, USA-made imprinting processes. Each process brings different advantages, carefully designed to elevate our bandannas a step above other products. With our commitment to quality and artistic excellence, we ensure that your clients will be impressed by the unique and attention-grabbing designs we create.

Trust Bandanna Warehouse for all your custom bandanna needs, because we know that an eye-catching design can make all the difference.

1. Digital

FULL COLOR TO PHOTOGRAPHIC

Low 50pc Minimum!

Full color designs, photography or edge-to-edge step & repeat logo impact!

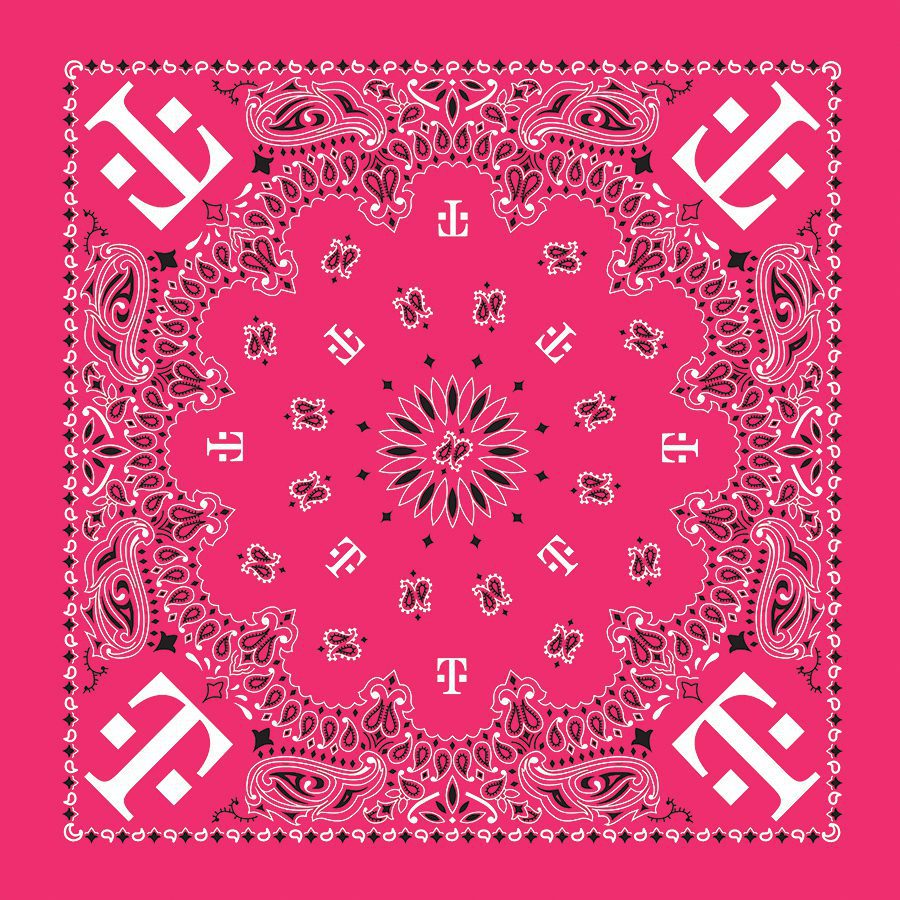

2. SILKSCREEN

MOST POPULAR PRINT PROCESS

Low 50pc Minimum!

Big 18″ x 18″ custom logo and design print area to tell a brand story.

3. Heat transfer

FULL COLOR DECAL

Low 50pc Minimum!

Up to 5″ x 5″ size full color to photographic transfer for added brand design on solid colors or novelty pattern bandannas!

4. EMBROIDERY

PESONALIZED IMPACT

Low 50pc Minimum!

Big 18″ x 18″ custom logo and design print area to tell a brand story.

5. ROTARY

LOWEST COST PRINT PROCESS

3,000pc Minimum!

More colors, faster production, for a softer feel bandanna printed with water based, pms matched pigment dyes.

6. DUPLEX

EXCLUSIVE 2 SIDED PRINT PROCESS

3,000pc Minimum!

Innovative printing, 100% saturation on both sides using water based 1-2/c pigment dyes.

ROTARY

Fast production times – Up to 8 Colors

We use the rotary printing process to print your bandannas. Rotary printing creates a softer bandanna because the eco-friendly, water-based pigment dyes are absorbed into the cloth. Your design is printed on white cloth so colors stay true. Initial screens are included in pricing.

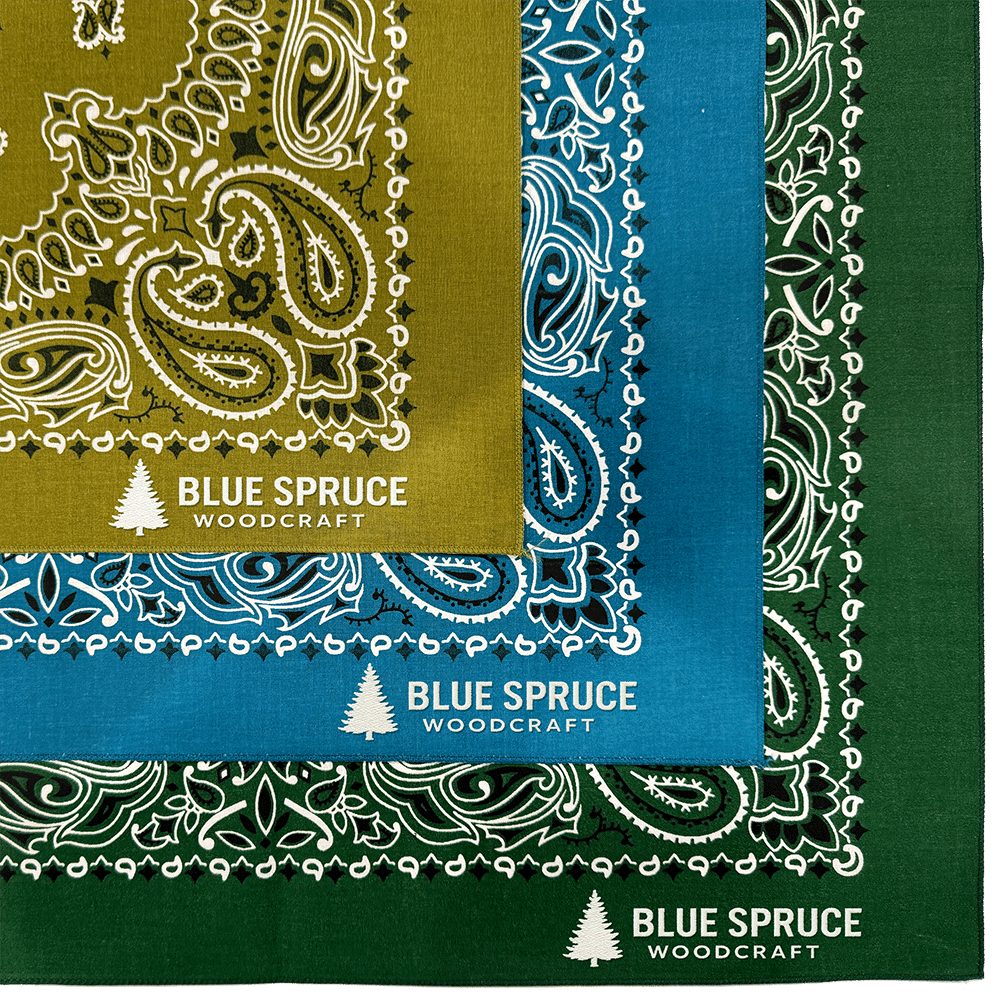

SCREEN PRINT

1 – 4 COLORS – LOW MINIMUMS – ECONOMICAL

In silkscreen printing, the imprint color is laid down on a dyed piece of cloth. Note that silkscreen printing doesn’t allow for edge-to-edge printing; all designs must have a border (for example, when starting with a blank 22” bandanna, the imprint size will be 18” x 18”).

DUPLEX

Innovative printing (two sides with pigment dyes)

The process is a lost art on fabrics of today. The fabric is printed on both sides in Duplex Printing. Thus in this method a clear outline is produced on both sides of the fabric. The design is applied so skillfully by the printing cylinders that the result may be mistaken for a woven design.

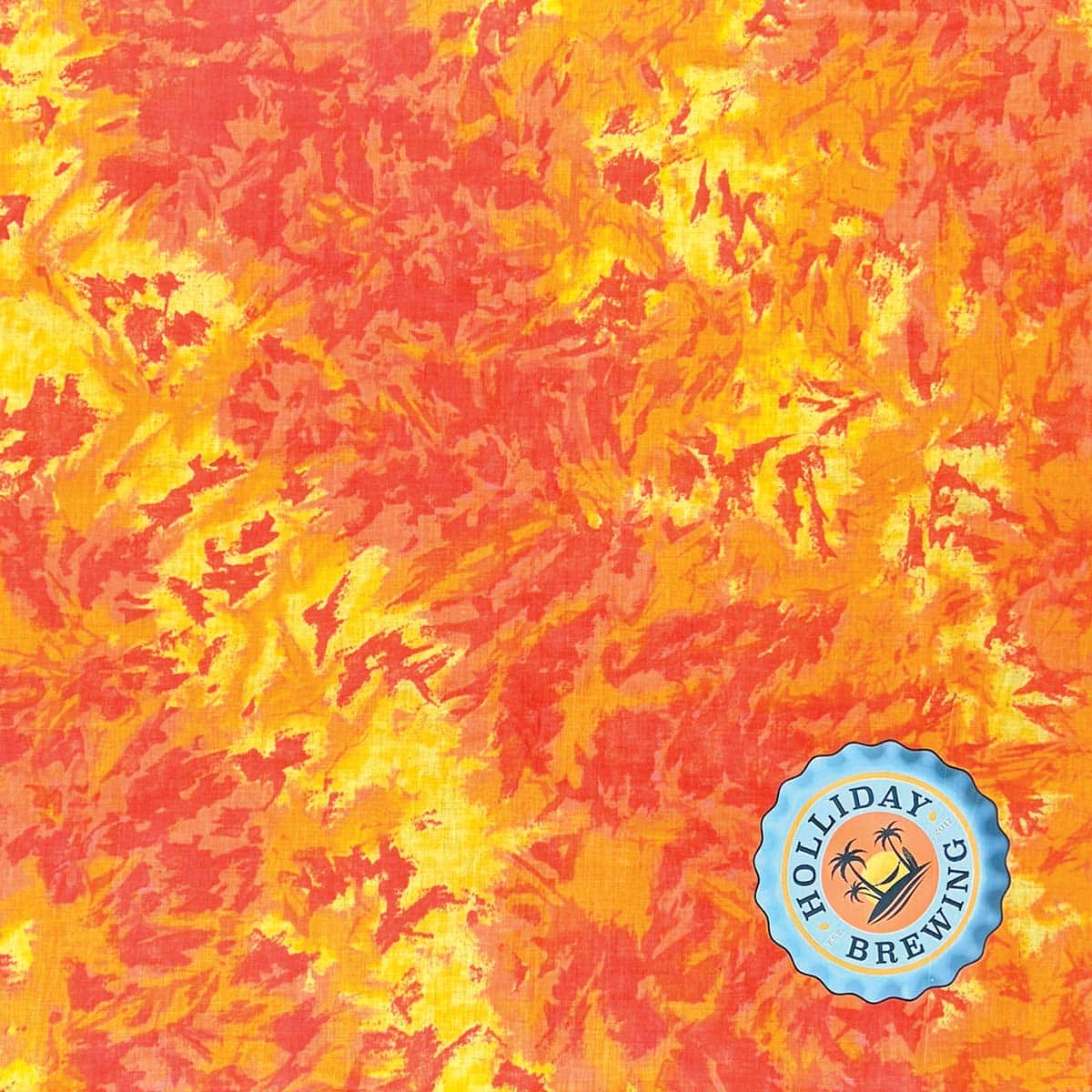

DIGITAL

FULL COLOR TO PHOTOGRAPHIC

This versatile printing process involves printing an image directly from a computer-generated design file onto fabric substrates by way of a large-format inkjet printer. Custom Digital Bandannas are created starting with a white cloth before full-color graphics are printed on the front (the back is left solid white).

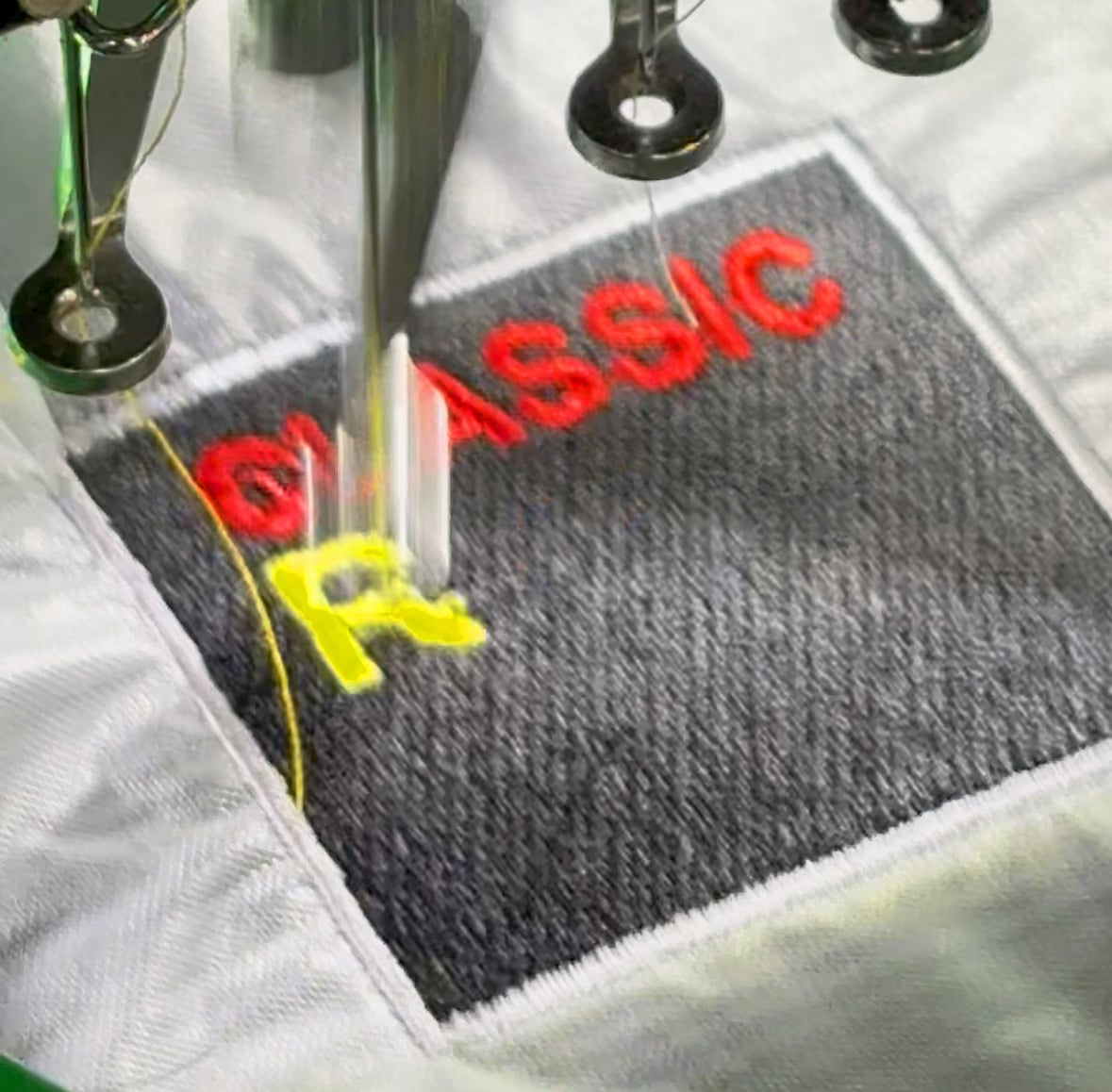

EMBROIDERY

TELL YOUR BRAND STORY!

Add a personal touch with subtle but stylish logo flair! Eco-sustainable and long lasting!

HEAT TRANSFER

FULL COLOR DECAL

Up to 5″ x 5″ size full color to photographic transfer for added brand design on solid colors or novelty bandannas.